Using steel rule dies, we can die cut foam, sheet plastic, corrugated plastic, chipboard, fabric, rubber, felt, cork, thin metals, wood, acrylic, composites, fiberglass, magnets, sponge, custom die cuts or any other flat material normally found in the industry. For a complete listing, see our materials section.

Custom Die Cutting Machinery: We use only flat bed die cutters at Mag-Knight. A Flat bed die cutter has two parallel platens which exert pressure on a steel rule die. This creates a part with very close tolerance as close as .015. Here is a picture of a flat bed die cutter…

Custom Die Cutting environment: All of the products we cut require us to have a very clean environment. Since many are consumer products, we must be very careful to ensure that the they maintain their perfect appearance. This same careful attention to detail will apply to your job, large or small.

Custom Die Cutting environment: All of the products we cut require us to have a very clean environment. Since many are consumer products, we must be very careful to ensure that the they maintain their perfect appearance. This same careful attention to detail will apply to your job, large or small.

Video Demonstration: Watch Smith® Goggles being die cut in the die cutting demonstration to the right. Click on the title to watch the movie. If you have ever wondered how it is done, this will answer it!

Custom Die Cutting Steel Rule Dies

The steel rule die is the heart of die cutting. Bent metal blades are positioned in a wooden board to form a “cookie cutter”. This allows perfect duplication of your parts within .020″ every time. Complex shapes, stars, circles, and many different patterns are possible with a steel rule die. This tooling cost will be delineated separately in your quote from Mag-Knight. For a quote on your job see our Quotation Form page

Accuracy / Quality Assurance

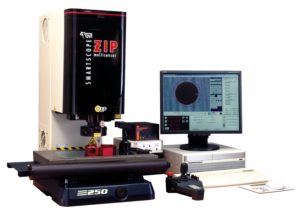

We use the very latest Statistical Process Control methods to verify part accuracy throughout the manufacturing run. Shown here is our OGP Smart scope with can optically measure parts to within .0001″ if required. We can provide measurements with every batch as part of our C of C documentation.